To troubleshoot Allison Transmission PTO issues, inspect the electrical connections and check for error codes. Verify the PTO enable switch and ensure proper hydraulic pressure.

Allison Transmission PTO (Power Take-Off) systems are essential for transferring engine power to auxiliary equipment. Accurate troubleshooting can prevent downtime and costly repairs. Start by examining the electrical connections for any signs of corrosion or damage. Error codes can provide critical insights into potential problems.

Ensure the PTO enable switch is functioning correctly. Check hydraulic pressure to ensure it meets the required specifications. Regular maintenance and timely inspections can extend the life of your PTO system. Proper troubleshooting helps in identifying issues early, ensuring smooth and efficient operation.

Introduction To Allison Transmission Pto Issues

Allison Transmissions are known for their reliability and efficiency. However, even the best systems face issues. Power Take-Off (PTO) units can experience problems. Understanding these issues can save time and money.

Common Pto Problems In Allison Transmissions

Common PTO problems include leaks, overheating, and noise. Below is a table summarizing these issues:

| Problem | Description | Possible Causes |

|---|---|---|

| Leaks | Fluid leaking from the PTO unit | Worn seals or gaskets |

| Overheating | PTO unit becomes too hot | Insufficient lubrication, clogged filters |

| Noise | Unusual sounds from the PTO | Worn gears or bearings |

Signs Of Pto Malfunction

Recognizing signs of PTO malfunction is crucial. Here are some key indicators:

- Unusual noises like grinding or whining

- Fluid leaks under the vehicle

- Overheating of the PTO unit

- Reduced performance or power output

These signs suggest PTO issues. Address them promptly to avoid further damage.

Pre-troubleshooting Checks

Before diving into complex troubleshooting, conduct basic checks first. These initial steps can save time. They help identify obvious issues quickly. Here are some essential pre-troubleshooting checks.

Verifying Transmission Fluid Levels

Low fluid levels can cause transmission problems. Check the fluid levels using the dipstick. Ensure the vehicle is on a level surface.

Steps to verify fluid levels:

- Park the vehicle on a flat surface.

- Start the engine and let it warm up.

- Locate the transmission dipstick.

- Pull out the dipstick and wipe it clean.

- Reinsert the dipstick fully, then pull it out again.

- Check the fluid level on the dipstick.

Fluid should be between the “Full” and “Add” marks. If low, add the recommended fluid type.

Inspecting For Visible Damage

Visible damage can indicate underlying issues. Inspect the transmission and PTO unit carefully.

Key areas to inspect:

- Transmission housing for cracks or damage.

- PTO unit for any signs of wear.

- Fluid leaks around seals and gaskets.

- Loose or damaged wiring and connectors.

Address any visible damage immediately. This can prevent further complications.

Next: Genie Gth 844 Troubleshooting

Pto Engagement Challenges

Experiencing issues with your Allison Transmission PTO can be frustrating. The Power Take-Off (PTO) system is crucial for your vehicle’s functionality. If the PTO does not engage, it can halt your operations. Let’s explore common PTO engagement challenges and solutions.

Investigating Solenoid Faults

The solenoid is an essential part of the PTO system. A faulty solenoid can prevent the PTO from engaging. Here are steps to identify solenoid issues:

- Check the solenoid for power supply. Use a multimeter to test it.

- Inspect the wiring for any visible damage.

- Ensure the solenoid is grounded properly.

If the solenoid is not receiving power, the issue might be upstream. Check the control switches and fuse. Replace any damaged parts immediately.

Adjusting The Pto Engagement Cable

The PTO engagement cable can also cause issues. If the cable is loose or damaged, the PTO will not engage. Follow these steps to adjust the cable:

- Locate the PTO engagement cable on your vehicle.

- Check for any visible signs of wear or damage.

- Adjust the cable tension using the adjustment screw.

- Test the PTO engagement after adjustment.

Ensure the cable is not too tight or too loose. Proper adjustment is crucial for smooth PTO operation.

| Issue | Possible Cause | Solution |

|---|---|---|

| PTO not engaging | Faulty solenoid | Check power and grounding |

| PTO engagement delay | Loose engagement cable | Adjust cable tension |

Addressing these common issues can restore your PTO system. Regular maintenance and prompt troubleshooting ensure smooth operations.

Electrical Diagnostics

Electrical diagnostics are vital for troubleshooting Allison Transmission PTO issues. Identifying electrical problems early can prevent more significant damage. This section covers essential steps in testing electrical connections and solving common electrical issues.

Testing Electrical Connections

Testing electrical connections ensures your PTO system functions correctly. Follow these steps to test connections:

- Turn off the vehicle’s power.

- Inspect all wiring for visible damage.

- Use a multimeter to check for continuity.

- Test the voltage at each connection point.

- Ensure all connections are secure and corrosion-free.

A well-maintained electrical system is crucial for PTO performance.

Solving Common Electrical Issues

Common electrical issues can hinder your PTO’s operation. Here are solutions for frequent problems:

| Issue | Solution |

|---|---|

| Corroded Connections | Clean connections with a wire brush. |

| Blown Fuses | Replace fuses with correct ratings. |

| Faulty Wiring | Replace damaged wires immediately. |

| Loose Connections | Tighten all loose connections securely. |

Addressing these issues promptly can extend the life of your PTO system. Regular inspections and maintenance are key to preventing electrical problems. Keep your equipment running smoothly with proper care.

Read: GMC Acadia Troubleshooting

Hydraulic System Analysis

Understanding the hydraulic system in an Allison Transmission is crucial. The system ensures smooth operation and longevity of your transmission. Analyzing the hydraulic system can help identify problems early. This section will focus on key areas of hydraulic system analysis.

Assessing Hydraulic Pressure

Hydraulic pressure plays a vital role in the transmission’s performance. Checking the pressure ensures the system operates correctly.

- Use a hydraulic pressure gauge.

- Connect the gauge to the test port.

- Start the engine and monitor the readings.

Refer to the manufacturer’s specifications for the correct pressure range. Low pressure may indicate a pump issue or fluid contamination. High pressure might suggest a blocked line or faulty relief valve.

Identifying Hydraulic Leaks

Hydraulic leaks can cause significant problems in your transmission. Identifying leaks early can prevent costly repairs.

- Inspect all hoses and connections.

- Look for signs of fluid on the ground.

- Check for wet spots on the transmission body.

Use a UV dye to detect small leaks. Add the dye to the hydraulic fluid. Use a UV light to spot the leak. Leaks can occur at seals, fittings, or hoses. Replace any damaged components promptly.

| Symptom | Possible Cause |

|---|---|

| Low Hydraulic Pressure | Pump issue, fluid contamination |

| High Hydraulic Pressure | Blocked line, faulty relief valve |

| Fluid on Ground | Leak at hose or connection |

Mechanical Component Inspection

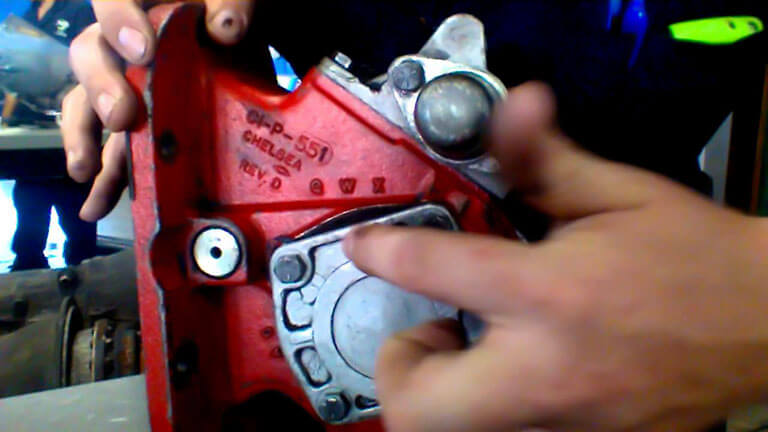

Inspecting the mechanical components of an Allison Transmission PTO (Power Take-Off) system is crucial. This can prevent breakdowns and extend the life of the equipment. This section will guide you through the essential steps. We will focus on checking gear conditions and evaluating shaft and bearing wear.

Checking Gear Conditions

Gears are the heart of any transmission system. Begin by examining each gear for wear and tear. Look for worn teeth, chips, and cracks. These can cause inefficiencies and failures.

Use a magnifying glass to inspect small gears. This helps you spot minor defects. Rotate each gear and check for smooth movement. Any grinding or resistance indicates a problem.

Here’s a quick checklist for gear inspection:

- Check teeth for wear

- Look for cracks or chips

- Ensure smooth rotation

Evaluating Shaft And Bearing Wear

Shafts and bearings support the gears. They ensure smooth movement and power transfer. Start by examining the shaft surfaces. Look for signs of wear or corrosion. Use a micrometer to measure the shaft diameter. Compare the measurements with the manufacturer’s specifications.

Next, inspect the bearings. Remove the bearings and check for any play or looseness. Rotate the bearings and listen for noise. A noisy bearing usually means it’s worn out. Replace any faulty bearings immediately.

Here’s a table to summarize the steps for evaluating shafts and bearings:

| Component | Inspection Steps |

|---|---|

| Shaft |

|

| Bearings |

|

Proper inspection of gears, shafts, and bearings can save you from costly repairs. This ensures your Allison Transmission PTO system runs smoothly.

Next: John Deere Fuel System Troubleshooting

Troubleshooting Control System Errors

Troubleshooting Control System Errors in Allison Transmission PTO can be challenging. The control system ensures smooth and efficient operation. Identifying and fixing errors can save time and money. Below are key steps to resolve control system errors.

Resetting The Pto Control Module

Resetting the PTO control module is a crucial step. It helps clear any temporary glitches. Follow these steps to reset the module:

- Turn off the engine and remove the key.

- Disconnect the battery for 5 minutes.

- Reconnect the battery and start the engine.

- Check if the PTO control module is functioning properly.

If the issue persists, consult the vehicle’s manual. Ensure all connections are secure and clean.

Calibrating Pto Control Settings

Correct calibration of PTO control settings ensures optimal performance. Follow these steps to calibrate:

- Access the PTO control settings via the vehicle’s interface.

- Navigate to the calibration menu.

- Follow the on-screen instructions to calibrate.

- Save the settings and restart the engine.

Regular calibration helps maintain efficiency and prevents errors. For best results, refer to the manufacturer’s guidelines.

| Step | Action | Outcome |

|---|---|---|

| 1 | Turn off engine and remove key | Prepares for reset |

| 2 | Disconnect battery for 5 minutes | Clears temporary glitches |

| 3 | Reconnect battery and start engine | Resets control module |

| 4 | Check PTO control module | Verifies proper function |

Maintenance Tips For Longevity

Proper maintenance ensures your Allison Transmission PTO performs well. Regular care helps avoid costly repairs. Follow these tips to extend the lifespan of your PTO.

Regular Maintenance Schedule

Set a regular maintenance schedule. Check the PTO weekly. Inspect for wear and tear. Look for leaks or loose parts. Address issues quickly to prevent bigger problems.

| Maintenance Task | Frequency |

|---|---|

| Fluid Level Check | Weekly |

| Inspect for Leaks | Weekly |

| Lubricate Moving Parts | Monthly |

| Full System Inspection | Quarterly |

Best Practices For Pto Care

- Use manufacturer-approved fluids.

- Avoid overloading the PTO.

- Keep the PTO clean and free of debris.

- Store the vehicle in a dry place.

Following these tips will help your PTO last longer. Regular checks and proper care keep it running smoothly. Preventive maintenance is key to longevity.

When To Seek Professional Help

Maintaining your Allison Transmission and PTO (Power Take-Off) system is crucial. Sometimes, issues may arise that are beyond basic troubleshooting. In such cases, seeking professional help can save time and money. Below are key points to help you identify when professional assistance is necessary.

Identifying Complex Transmission Issues

Some transmission issues may appear simple but are complex. Recognizing these can prevent further damage. Here are signs that indicate complex problems:

- Unusual Noises: Grinding or whining sounds signal internal issues.

- Fluid Leaks: Persistent leaks suggest seal or gasket problems.

- Erratic Shifting: Inconsistent gear changes point to electronic or mechanical faults.

- Warning Lights: Dashboard alerts indicate serious transmission issues.

If you notice any of these signs, it’s best to consult a professional. Attempting to fix these on your own can worsen the problem.

Finding Qualified Allison Transmission Experts

Choosing the right expert is essential for resolving transmission issues effectively. Here are steps to find a qualified Allison Transmission professional:

- Check Certifications: Look for ASE-certified technicians.

- Read Reviews: Customer reviews provide insight into the technician’s skill.

- Ask Questions: Inquire about their experience with Allison Transmissions.

- Get Estimates: Request quotes to compare prices and services.

By following these steps, you can ensure your Allison Transmission is in capable hands. This will help you avoid costly mistakes and ensure the longevity of your equipment.

Conclusion: Ensuring Reliable Pto Function

Ensuring your Allison Transmission PTO functions reliably requires understanding common issues and solutions. Regular maintenance is key to avoiding breakdowns and ensuring longevity. This section summarizes essential steps and highlights maintenance importance.

Summarizing Key Troubleshooting Steps

Understanding key troubleshooting steps helps keep your PTO working efficiently. Here’s a quick summary:

- Check Fluid Levels: Low fluid can cause overheating and damage.

- Inspect Electrical Connections: Ensure all wires are secure and undamaged.

- Monitor Pressure Gauges: Abnormal readings indicate potential issues.

- Listen for Unusual Noises: Strange sounds may signal mechanical problems.

- Examine Filters: Clogged filters restrict fluid flow and cause overheating.

Following these steps can prevent costly repairs and downtime. Regular checks ensure your PTO remains reliable and efficient.

Emphasizing The Importance Of Regular Maintenance

Regular maintenance is crucial for the longevity of your PTO. Simple tasks can make a big difference:

- Schedule Inspections: Regular checks catch issues early.

- Replace Worn Parts: Timely replacement prevents further damage.

- Keep Clean: Dirt and debris can cause wear and tear.

- Lubricate Moving Parts: Proper lubrication reduces friction and wear.

Maintaining a schedule ensures your PTO runs smoothly. Investing time in maintenance saves money on repairs.

In summary, understanding troubleshooting steps and maintaining a regular schedule keeps your Allison Transmission PTO reliable.

Frequently Asked Questions

What Causes Pto Issues In Allison Transmission?

PTO issues may arise from low fluid levels, worn-out gears, or electrical faults in the system.

How Do You Check Pto Fluid Levels?

Use the dipstick to check fluid levels, ensuring they are within the recommended range.

Why Is My Pto Not Engaging?

A PTO might not engage due to faulty switches, low fluid, or mechanical wear.

Can Low Fluid Affect Pto Performance?

Yes, insufficient fluid can lead to overheating and inefficient PTO operation.

How To Fix Electrical Faults In Pto?

Inspect and replace damaged wires, connectors, or switches to resolve electrical issues.

Conclusion

Effective Allison Transmission PTO troubleshooting ensures smooth operations. Follow our tips to diagnose and resolve issues quickly. Regular maintenance is crucial. Keep your equipment running efficiently and avoid costly downtime. Stay proactive with your PTO care to maximize performance and reliability.

For more detailed advice, always consult your service manual or a professional technician.