To troubleshoot a Viking gate operator, check for power supply issues and inspect the control board for visible damage. Ensure all connections are secure and the system is properly programmed.

Viking gate operators are essential for secure and efficient gate automation. These devices ensure smooth operation of gates in residential and commercial properties. Troubleshooting these systems can seem daunting, but with a systematic approach, common issues can be easily resolved.

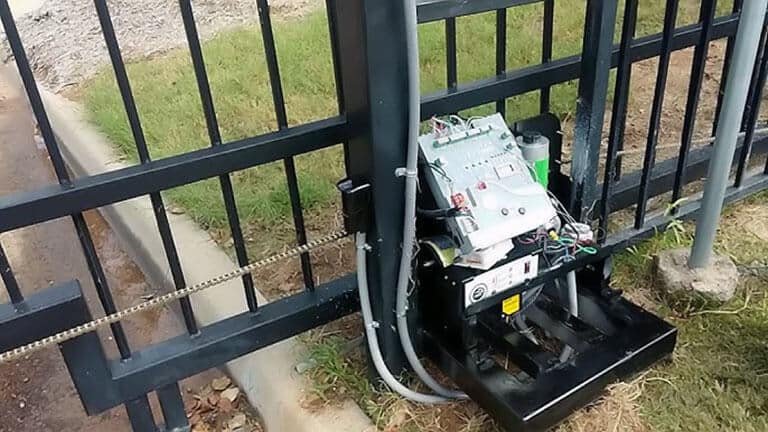

Begin by checking the power supply to the gate operator, as power interruptions are a frequent cause of malfunction. Inspect the control board and wiring for any visible damage or loose connections. Proper programming is also crucial for the gate operator to function correctly. Regular maintenance and timely troubleshooting can extend the lifespan of your Viking gate operator.

Introduction To Viking Gate Operators

Viking gate operators are known for their efficiency and strength. They help in controlling gate access for homes and businesses. These devices are popular due to their reliability and advanced features.

Popularity And Reliability

Viking gate operators have become very popular. This popularity is due to their strong build and dependable performance. People trust them to keep their properties safe.

Their durability ensures they work well in different weather conditions. Viking gate operators are designed to last for many years. They require minimal maintenance, making them a favorite choice.

Common Models In Use

Several models of Viking gate operators are commonly used. Each model offers unique features to meet various needs.

- Viking K-2: This model is perfect for residential use. It is compact and efficient.

- Viking G-5: Ideal for both residential and commercial applications. It provides robust security.

- Viking H-10: This heavy-duty model is suited for industrial use. It offers high reliability and strength.

These models are easy to install and operate. They also come with user-friendly controls. These features make them a preferred choice for many users.

| Model | Best For | Features |

|---|---|---|

| Viking K-2 | Residential | Compact, efficient, user-friendly |

| Viking G-5 | Residential and Commercial | Robust security, reliable |

| Viking H-10 | Industrial | Heavy-duty, high strength |

Symptoms Of Malfunctioning Gate Operators

A malfunctioning Viking gate operator can disrupt daily routines. Identifying common symptoms early can help in troubleshooting and fixing the issues. Below are some key symptoms to watch for.

Unresponsive Gates

Unresponsive gates are a clear sign of trouble. Common causes include:

- Dead remote batteries

- Faulty wiring

- Power supply issues

First, check if the remote control has fresh batteries. Ensure the power supply is active and connected. If the gate remains unresponsive, inspect the wiring for visible damage.

Noisy Operation

Noise during gate operation is a sign of wear. Key causes include:

- Worn-out gears

- Lack of lubrication

- Misaligned components

Regularly lubricate the moving parts. If the noise persists, check for gear wear. Misaligned components can also cause noise; ensure everything is properly aligned.

Irregular Movement

Gates that move erratically pose a security risk. Possible reasons include:

- Sensor issues

- Obstructions

- Control board malfunctions

First, clear any obstructions along the gate’s path. Check the sensors for dirt or damage. A faulty control board may need professional inspection.

| Symptom | Possible Cause | Solution |

|---|---|---|

| Unresponsive Gates | Dead remote batteries | Replace batteries |

| Noisy Operation | Worn-out gears | Lubricate and check gears |

| Irregular Movement | Sensor issues | Clean or replace sensors |

By understanding these symptoms, you can take timely action. This helps ensure the smooth operation of your Viking gate operator.

Safety First: Pre-troubleshooting Checks

Before starting any troubleshooting, safety must be your first priority. Doing pre-troubleshooting checks ensures your safety and the proper functioning of the Viking gate operator. These checks help identify potential issues before diving into detailed troubleshooting.

Power Source Verification

Check if the gate operator is receiving power. This is crucial. Verify the power source to ensure it’s turned on and functioning.

- Look at the circuit breaker. Is it tripped?

- Check the power outlet. Is it working?

- Inspect the power cord. Is it damaged?

Obstacle Inspection

Make sure there are no obstacles blocking the gate. Obstacles can hinder the gate’s operation.

- Look for objects near the gate.

- Check for debris on the track.

- Ensure the gate path is clear.

Emergency Release Procedure

Familiarize yourself with the emergency release procedure. This is vital for safety.

- Locate the emergency release lever.

- Pull the lever to disengage the gate.

- Manually open or close the gate.

Knowing the emergency release procedure ensures you can operate the gate manually if needed.

Basic Troubleshooting Steps

Having trouble with your Viking gate operator? Don’t worry! Follow these basic troubleshooting steps to get your gate working smoothly again. Whether it’s a system reset or a manual operation test, these steps will help you identify and fix common issues.

Resetting The System

Resetting your Viking gate operator is often the first step. Here’s how:

- Turn off the power supply to the gate operator.

- Wait for about 30 seconds.

- Turn the power back on.

This simple reset can solve many minor glitches. Always check the operator’s manual for specific instructions.

Remote Control And Receiver Issues

If your remote control isn’t working, check these points:

- Ensure the remote has fresh batteries.

- Check if the remote is paired correctly with the receiver.

- Inspect the receiver’s antenna for any damage.

If issues persist, try reprogramming the remote. Refer to the user manual for detailed steps.

Manual Operation Test

Testing the gate manually helps determine if the issue is mechanical. Follow these steps:

- Disengage the gate operator using the manual release lever.

- Try opening and closing the gate by hand.

- Check for any obstructions or unusual resistance.

If the gate moves smoothly, the problem might be with the operator. If not, inspect the gate tracks and hinges.

For a quick overview, here’s a handy table:

| Step | Action |

|---|---|

| Resetting | Turn off and on the power supply |

| Remote Issues | Check batteries, pairing, and antenna |

| Manual Test | Disengage operator and check gate movement |

These basic troubleshooting steps are your first line of defense. Keep your gate operator running smoothly!

Electrical Issues And Solutions

Electrical issues are common with Viking gate operators. Proper troubleshooting can save you time and money. This section focuses on diagnosing and fixing electrical problems.

Checking The Fuse And Transformer

First, locate the fuse in your Viking gate operator. Remove the fuse carefully. Inspect it for any signs of damage or burnout. If the fuse is damaged, replace it with a new one. Ensure the new fuse matches the original specifications.

Next, check the transformer. Use a multimeter to measure the voltage output. Compare the reading with the manufacturer’s specifications. If the voltage is incorrect, the transformer may need replacement. Always use a transformer that meets the operator’s requirements.

Wiring And Connection Fixes

Inspect the wiring for any visible damage. Look for frayed wires, loose connections, or corrosion. Use a wire stripper to clean the ends of the wires if needed. Tighten any loose connections using a screwdriver.

Check the control board connections. Ensure all wires are securely attached. Use a multimeter to test the continuity of the wires. If a wire fails the continuity test, replace it. Secure all connections with electrical tape to prevent future issues.

For complex wiring issues, refer to the operator’s manual. The manual will provide a detailed wiring diagram. Follow the diagram carefully to ensure correct connections.

Mechanical Adjustments

Mechanical adjustments are crucial for the smooth operation of your Viking gate operator. Regular maintenance can prevent many issues. Proper adjustments ensure your gate works efficiently and safely. This section covers essential mechanical adjustments.

Lubrication For Smooth Operation

Lubrication keeps your gate operator running smoothly. It reduces friction and wear. Use a high-quality lubricant on moving parts. Focus on the hinges, rollers, and chains. Lubricate these parts every six months.

- Apply lubricant to all moving parts.

- Use a cloth to remove excess lubricant.

- Check for any unusual noises or resistance.

Ensure you use the right type of lubricant. Check your Viking gate operator manual. The manual will recommend the best lubricant. Proper lubrication extends the life of your gate operator.

Gate Alignment And Hinge Maintenance

Gate alignment is crucial for smooth operation. Misalignment can cause the gate to jam. Check the alignment regularly. Use a level to ensure the gate is straight.

| Step | Description |

|---|---|

| 1 | Check if the gate is level. |

| 2 | Adjust the hinges if needed. |

| 3 | Ensure the gate opens and closes smoothly. |

Hinge maintenance is also important. Inspect the hinges for rust or damage. Clean the hinges regularly. Apply lubricant to the hinges. This will reduce wear and tear.

By maintaining proper gate alignment and hinge functionality, you can avoid many operational issues. Regular checks and adjustments will keep your gate operator in top condition.

Advanced Troubleshooting Techniques

Viking gate operators are known for their reliability and efficiency. However, even the best equipment can face issues. This section covers advanced troubleshooting techniques to solve common problems. Below are detailed steps for diagnosing and fixing issues.

Diagnostic Codes And Their Meanings

Understanding diagnostic codes is crucial for effective troubleshooting. Viking gate operators display specific codes to indicate various issues. Here are some common codes and their meanings:

| Code | Meaning |

|---|---|

| 01 | Obstacle detected in path |

| 02 | Gate not responding |

| 03 | Low battery |

| 04 | Motor overheating |

If you see a code, refer to the table above. Identify the issue and take appropriate action. For example, if you see code 01, check for obstacles. Remove any objects blocking the gate.

Adjusting Settings And Limits

Adjusting settings and limits is essential for smooth operation. Follow these steps to adjust your Viking gate operator:

- Enter programming mode: Press and hold the program button until the LED blinks.

- Adjust open/close limits: Use the up and down arrows to set the desired limits.

- Save settings: Press the program button again to save.

Make sure you test the gate after adjusting. Ensure the gate opens and closes smoothly. If issues persist, recheck the settings and limits.

For complex adjustments, refer to the user manual. It provides detailed instructions for various settings. Always ensure the power is off before making any adjustments.

When To Call A Professional

Viking gate operators are reliable, but sometimes they face issues. Knowing when to call a professional can save time and money. This section helps you decide when expert help is needed.

Identifying Complex Issues

Some problems are simple, like dead batteries or loose wires. Complex issues need professional attention. These can include:

- Gate not moving smoothly

- Unusual noises from the motor

- Electrical problems

- Software glitches

Professionals can quickly diagnose and fix these problems. They have the right tools and knowledge.

Benefits Of Professional Maintenance

Regular professional maintenance keeps your gate operator in good condition. Here are some benefits:

| Benefit | Explanation |

|---|---|

| Extended Lifespan | Regular checks prevent major issues. |

| Safety | Professionals ensure all safety features work. |

| Efficiency | Well-maintained gates run smoothly and efficiently. |

Scheduled maintenance by experts ensures your gate operates smoothly. It minimizes unexpected breakdowns.

Preventative Measures For Longevity

Ensuring the longevity of your Viking Gate Operator is crucial. Regular care and updates can extend its life. This section covers essential steps for maintaining your gate operator. Follow these preventative measures to keep your gate in top shape.

Routine Maintenance Tips

Routine maintenance is the first step to a long-lasting Viking Gate Operator. Here are some tips:

- Lubricate moving parts regularly to avoid wear and tear.

- Inspect the gate for any signs of damage or rust.

- Clean the gate and operator to remove dirt and debris.

- Check the electrical connections and tighten any loose wires.

- Test the safety features, such as sensors and reverse mechanisms.

- Replace worn-out parts immediately to prevent further damage.

Upgrade Options For Enhanced Performance

Consider upgrading certain components for better performance and longevity. Here are some options:

- Smart Controllers: Upgrade to smart controllers for remote access and monitoring.

- High-Quality Sensors: Install better sensors for improved safety and efficiency.

- Durable Motors: Use more durable motors that last longer and perform better.

- Solar Panels: Add solar panels for an eco-friendly power source.

- Battery Backup: Ensure the gate operates during power outages with a battery backup.

Conclusion: Ensuring Continuous Operation

Ensuring the continuous operation of your Viking gate operator is crucial. Regular maintenance and troubleshooting can prevent unexpected breakdowns. Let’s summarize the key points and encourage proactive care.

Summary Of Key Points

| Key Points | Description |

|---|---|

| Regular Inspections | Check the gate operator monthly for any signs of wear. |

| Lubrication | Keep all moving parts well-lubricated to ensure smooth operation. |

| Electrical Components | Inspect wiring and connections for any signs of damage. |

| Software Updates | Ensure the operator’s software is up-to-date for optimal performance. |

Encouragement For Proactive Care

- Schedule Routine Maintenance: Set regular intervals for check-ups.

- Educate Users: Teach users basic troubleshooting steps.

- Have Spare Parts: Keep essential spare parts handy.

- Professional Help: Don’t hesitate to call professionals for complex issues.

Proactive care can save time and money. It also ensures your Viking gate operator works smoothly.

Frequently Asked Questions

How Do I Reset My Viking Gate Operator?

To reset your Viking gate operator, locate the reset button on the control panel and press it.

Why Is My Viking Gate Not Opening?

Check for obstructions, power supply issues, or remote control battery problems that could prevent your gate from opening.

What Causes A Viking Gate To Beep?

A beeping Viking gate often indicates a low battery or a fault in the system that needs attention.

How Do I Program A Viking Gate Remote?

Press the learn button on the control panel, then press the desired button on the remote to program it.

Why Is My Viking Gate Moving Slowly?

Slow movement can be caused by low battery power, mechanical obstructions, or the need for lubrication on the moving parts.

Conclusion

Troubleshooting Viking gate operators can be straightforward with the right guidance. Follow our tips to ensure smooth operation. Regular maintenance and timely fixes will extend the lifespan of your gate system. Keep this guide handy for future reference. A well-maintained gate ensures security and peace of mind for your property.