For precise troubleshooting of Warrick level controls, refer to instructional videos available on platforms like YouTube. Additionally, Warrick’s official website and resources like manuals and trouble-shooting guides can provide detailed insights on diagnosing and resolving issues related to level controls.

Warrick level controls play a pivotal role in monitoring and maintaining liquid levels in various industrial and commercial applications. However, encountering issues with these controls is not uncommon, and troubleshooting becomes essential to ensure proper functionality. Whether it’s over-sensing or under-sensing the liquid, identifying and resolving these problems is crucial for efficient operation.

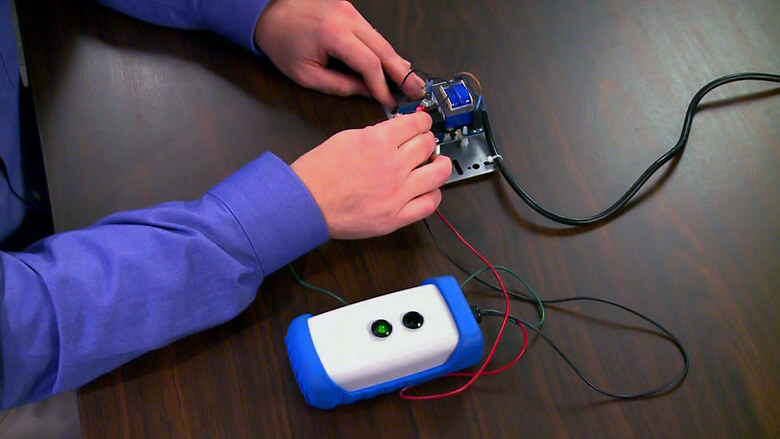

Understanding the wiring, conductivity principles, and precise diagnosis through gems sensors and controls can aid in effectively troubleshooting Warrick level controls. Furthermore, getting acquainted with concepts like relay operation, electrode connections, and probe testing can enhance your troubleshooting skills and ensure optimal performance of Warrick level controls.

Understanding Warrick Level Controls

Warrick level controls are designed to monitor and manage liquid levels in tanks, wells, and other similar applications. These controls are essential in preventing overflows and maintaining optimal levels in various industrial and commercial settings. Understanding the functionality and advantages of Warrick controls is crucial for ensuring their efficient operation and troubleshooting any issues that may arise.

Functionality of Warrick Controls

Warrick level controls are built on the concept of using a liquid’s conductive properties to complete a circuit, subsequently causing a control relay to actuate. This is achieved through the use of permanently-mounted stationary electrodes, providing precise accuracy, repeatability, and reliability without any moving parts. The controls come with different modes of operation, including single level service, differential service, relay activation, and inverse mode, each serving specific purposes in level monitoring and control. Understanding the functionality of each mode is key to proper utilization and troubleshooting.

Advantages of Using Warrick Controls

There are several advantages to using Warrick level controls. These include their simple and reliable operation, precise monitoring of liquid levels, and their ability to prevent overflows and underfills. Additionally, Warrick controls offer ease of installation and maintenance, making them a cost-effective solution for liquid level management in various industrial and commercial settings.

By comprehending the functionality and benefits of Warrick level controls, operators can effectively troubleshoot any issues that may arise and ensure seamless and efficient liquid level management.

Key Components Of Warrick Level Controls

Relay Operation

Understanding how the relay operates is crucial for troubleshooting Warrick level controls effectively.

Electrode System

The electrode system plays a vital role in the precision and reliability of Warrick level controls.

Common Issues With Warrick Level Controls

When dealing with Warrick Level Controls, it’s crucial to be aware of the common issues that may arise during operation. Understanding these issues and how to troubleshoot them can help ensure smooth functioning and accurate liquid level monitoring.

Over-sensing Of Liquid

Excessive liquid detection by Warrick Level Controls can lead to inaccurate readings and potential system malfunctions. This often occurs due to incorrect calibration or sensitivity settings.

Under-sensing Of Liquid

On the other hand, under-sensing of liquid can result in the control system failing to detect the presence of liquid when it’s below the set threshold. This issue commonly stems from electrode malfunctions or signal interference.

Diagnosing Warrick Level Control Problems

If you’re experiencing issues with your Warrick level control, it’s important to diagnose the problem accurately before attempting any repairs. By understanding the common problems that can occur and how to troubleshoot them, you can quickly get your system back up and running.

Testing Electrode Connections

To begin your troubleshooting process, start by checking the electrode connections. Any shorts or loose connections can result in inaccurate readings or the control not functioning at all. Here’s a simple step-by-step guide to test the electrode connections:

- Ensure that the power is turned off and the system is completely disconnected.

- Inspect the electrode terminals for any signs of damage, such as corrosion or loose wires.

- Use a multimeter to check the resistance between the electrode terminals. A high resistance reading indicates a poor connection.

- If necessary, tighten any loose connections or replace damaged electrodes.

Checking And Cleaning Electrodes

Dirty or contaminated electrodes can also lead to level control problems. Over time, a buildup of debris or scaling can interfere with the conductivity readings, resulting in inaccurate measurements. Follow these steps to check and clean the electrodes:

- Disconnect the power and remove the electrode assembly from the system.

- Inspect the electrodes for any signs of dirt, scale, or other contaminants. If necessary, use a soft brush or sponge to gently clean the surface.

- Rinse the electrodes with clean water to remove any remaining residue.

- Allow the electrodes to air dry completely before reassembling them into the system.

By testing the electrode connections and ensuring they are clean, you can often resolve common issues with Warrick level controls. However, if your troubleshooting efforts do not solve the problem, it may be necessary to consult a professional for further assistance.

Warrick Level Controls Troubleshooting Techniques

When it comes to troubleshooting Warrick Level Controls, it’s important to understand the different operation modes and techniques to identify and resolve any issues. This section will focus on two key troubleshooting techniques: Single Level Service Direct Mode and Differential Mode Operation. By familiarizing yourself with these techniques, you’ll be better equipped to resolve any problems that arise with your Warrick Level Controls.

Single Level Service Direct Mode

The Single Level Service Direct Mode is a commonly used operation mode for Warrick Level Controls. In this mode, the control relay is activated when the liquid reaches a specified level. However, if you encounter issues with the control relay not activating or activating prematurely, here are some troubleshooting steps to follow:

- Check the electrode connection to ensure there are no shorts. This can be done by inspecting the wiring and ensuring all connections are secure and free from damage.

- Inspect the electrodes to ensure they are clean and free from any build-up or debris. Dirty electrodes can interfere with the conductivity of the liquid and affect the control relay’s activation.

- Adjust the sensitivity settings on the Warrick Level Controls. Sometimes, the sensitivity may need to be fine-tuned to ensure accurate and reliable activation of the control relay.

By following these troubleshooting techniques, you can address common issues related to Single Level Service Direct Mode and ensure the proper functioning of your Warrick Level Controls.

Differential Mode Operation

Differential Mode Operation is another important feature of Warrick Level Controls. In this mode, the control relay is activated based on a specified difference in liquid levels between high and low setpoints. If you are experiencing difficulties with the differential mode operation, here are some troubleshooting tips:

- Verify the high and low setpoints. Ensure that they are set correctly and allow for an appropriate differential between high and low levels.

- Inspect the relay operation to confirm that it is functioning properly. A malfunctioning relay can affect the activation of the control relay in the differential mode.

- Monitor the relay status to identify any irregularities or inconsistencies. This can be done by using monitoring tools or visual inspections.

By following these troubleshooting techniques for Differential Mode Operation, you can effectively diagnose and resolve any issues you may encounter with your Warrick Level Controls.

Advanced Troubleshooting Methods

When dealing with Warrick Level Controls troubleshooting, it is essential to employ advanced methods for efficient problem-solving. Here are some advanced troubleshooting techniques to tackle complicated issues effectively.

Monitoring Relay Status

One crucial aspect of troubleshooting Warrick Level Controls is monitoring the relay status. This involves checking the relay’s operation to ensure it is functioning correctly and responding appropriately to the liquid levels.

Differential-inverse Mode

Another advanced troubleshooting method is utilizing the Differential-Inverse Mode. This mode allows for a more precise control mechanism, especially when dealing with varying liquid levels and complex control scenarios.

Conclusion And Recommendations

After going through the troubleshooting process for Warrick level controls, it is essential to summarize the key steps and consider how to get further support if needed. Understanding the troubleshooting process is vital for maintaining the efficiency and accuracy of the controls, ensuring smooth operations in various applications.

Summary Of Troubleshooting Process

When dealing with troubleshooting Warrick level controls, it is crucial to conduct a systematic approach that starts with inspecting the electrode connections and ensuring their cleanliness. If any issues are detected, the next step involves checking the controller settings, calibration, and monitoring relay status to identify the root cause of the problem. Furthermore, the differential service, relay operation, and mode of operation should be thoroughly examined to pinpoint any potential malfunctions. Once the troubleshooting steps have been completed, it’s essential to follow industry best practices for resolving issues and maintaining optimal performance.

Getting Support For Warrick Controls

Should you encounter difficulties beyond the scope of self-diagnosis and troubleshooting, reaching out for professional support is highly advisable. Gems Sensors, the manufacturer of Warrick controls, offers a comprehensive trouble shooting guide and resources for further assistance. Utilize their expertise and guidance to ensure the smooth functioning of your Warrick level controls, enabling efficient liquid level management in industrial and commercial settings.

Frequently Asked Questions

How Does A Warrick Relay Work?

A Warrick relay works by using a liquid’s conductive properties to complete a circuit and activate a control relay. It uses stationary electrodes for precise accuracy and reliability without any moving parts. Warrick relay problems usually fall into two categories: over-sensing or under-sensing the liquid.

How Do I Contact Gems Sensors?

To contact Gems Sensors, visit their website and use the “Locate A Distributor” feature for assistance.

How Do Warrick Level Controls Work?

Warrick level controls work by utilizing the conductive properties of liquids to complete a circuit and activate a control relay. With the help of stationary electrodes, they offer precise accuracy, repeatability, and reliability without any moving parts.

What Are Common Issues With Warrick Level Controls?

Common issues with Warrick level controls can usually be narrowed down to two categories: over-sensing or under-sensing the liquid. These problems can affect the accuracy and reliability of the control system.

Conclusion

In troubleshooting Warrick Level Controls, precise accuracy and reliability are key for effective operation. Understanding the relay operation and electrode connections is crucial for successful troubleshooting. By following troubleshooting guides, you can easily identify and resolve common issues with Warrick Controls, ensuring smooth functionality.